ORCID iD: 0000-0001-9430-773X

University of National and World Economy – Sofia, Bulgaria

https://doi.org/10.53656/igc-2024.05

Pages 49-59

Abstract. Business organizations are increasingly thinking about closing the production loop and moving closer to the so-called circular economy. On the other hand, changing from a linear model to a circular one is accompanied by many difficulties and unknowns. Achieving a regenerative system with zero waste emissions, full resource recovery, recycling and reuse poses a number of risks for business. This paper explores the possibility of using AI as an effective means of addressing risk in the transition to a circular economy and Industry 5.0. The results of the study identify the main relevant groups of risks and propose a methodology for their treatment, through different AI tools. This allows to achieve higher competitiveness and a smooth entry into Industry 5.0.

Keywords: Current Economic; Risk; Relationships of Circular Products

JEL: O10, O25, O32

- Introduction

The dynamics of the business environment show that, for the most part, current economic models are not sustainable enough. This is due to the manifestation of several risks related to overconsumption of material resources, problems with waste management policies, climate, biodiversity and health (Pathan et al., 2023). The problems are largely associated with growing needs, increasing customer demands and rapid production patterns, in complex with rapid consumer saturation of products, which also leads to short product life cycles. This type of consumption is associated with serious negative environmental impacts, such as high methane emissions generated by the decay of organic waste in landfills (Ximenes et al., 2015) for waste. Ximenes and his team (2015) provide irrefutable evidence that abundant waste production severely limits economic growth. All this is a reason to argue that the world economy needs a change focusing on recovery and regeneration, sparing natural resources and prioritizing on green and sustainable economic development (Morseletto, 2020). This can be achieved by using different approaches to extend the life cycle of products and their useful life or by returning product components to recycling and/or reuse systems (Noman et al., 2022). In this way durable, restorative and reformative products can be produced so that goods have the opportunity to be rented, replaced or shared where possible (Noman et al., 2022. The model to be followed to achieve this is the circular one. The approach in its implementation requires a high degree of integration and efficiency gains by implementing circular practices such as reuse, recycling and closed-loop systems (Pathan et al., 2023). The goals of a circular economy are related to creating a recovering economic system that has the ability to decouple economic growth from the consumption of finite resources by keeping products and their materials in use for longer periods of time, eliminating waste and pollution (Da Silva & Sehnem, 2022). The goals of a circular economy are related to creating a recovering economic system with the ability to decouple economic growth from the consumption of finite resources, keeping products and their materials in use for longer periods of time, eliminating waste and pollution (Da Silva & Sehnem, 2022). The circular economy is also associated with Industry 5.0. development concepts, where priorities are refocused on balanced and environmentally friendly, eco-equilibrium production and consumption. From what has been stated so far, it can be concluded that the circular economy is the replacement of the concept of the end of life cycle by recovery, a shift towards the use of renewable energy, accompanied by the elimination of the use of toxic substances that prevent reuse and return to the biosphere (Ghisellini et al., 2016). Therefore, the principles of circular economy can be synthesized in the main three: models eliminating pollution; preserving products as long as possible; use of materials that can be reused (Rathinamoorthy, 2019). The CE concepts are agreed by a large part of the business community but are very difficult to implement. This is due to the complex reorganisation of business processes, the amount of investment required; the inability to recycle and reuse several materials, etc. Transformation is complex and requires an innovative approach to implement. In this paper, the author argues that several of the main groups of risks associated with the implementation of a circular economy can be treated with different AI-based techniques and tools. The rationale for this is that AI is one of the foremost technologies that can provide multiple benefits using various algorithms for a smooth transition to CE. For example, real-time data analytics for supply chain management, cost reduction and carbon footprint reduction for sustainable development, automation of reverse logistics processes, waste generation impact assessment for waste management, sorting of different materials for recycling purposes, etc (Noman et al., 2022).

The research question posed in this paper is what are the main risk groups threatening the transition to a circular economy and how can AI reduce their frequency and or severity of impact? To answer this question, the paper sequentially presents the following parts: a backgrounder on AI in the circular economy, aiming to identify main directions of AI application to support the process; main groups of risks associated with AI application in the circular economy; research methodology and Results. The results of the study present a concept for addressing one of the most prevalent risk groups in the circular economy, namely the risks associated with the relationships and decision making between the actors in the circular product chain. The added value of this risk treatment measure lies in the support of the process with intelligent analysis by artificial intelligence.

- AI in CE Background

The use of AI in the circular economy is a topic of interest to many researchers of modern economic concepts and models. This is due to the transformative potential of AI using tools such as the Internet of Things (IoT) to collect data (Roberts et al., 2024) and conduct further ML predictive analysis, reverse logistics, improved process optimization and increased responsiveness (Chauhan et al., 2022). Furthermore, technologies such as Big Data, Blockchain, Cloud Computing and online digital platforms are enabling the multiplication of the circular economy. Advanced robotics, wearables and augmented reality (Ramadoss et al., 2018), based on AI are making their contributions in supply chains. With the help of AI-based technologies, knowledge is extracted about the material composition of products, their origin and properties, location, condition and availability, as well as their respective manufacturing processes and conditions for maintenance, disassembly and recycling (Barteková et al., 2022). In support of the importance of AI for CE, Ghoreishi and Happonen (2020) argue that the collaboration between the two enables the achievement of autonomous and remote monitoring of production efficiency and product lifecycle. By increasing business intelligence, each company can apply „individualized“ business models, which facilitates predictive analysis of their performance and enables appropriate monitoring throughout the organization’s lifecycle (Chauhan et al., 2021; Sterev & Biolcheva, 2023).

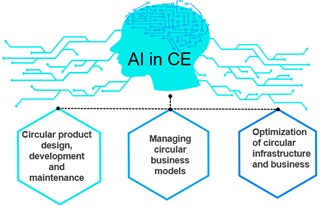

To highlight the clear contributions of AI to the circular economy, this paper identifies three key areas of application presented in Figure 1.

Figure 1. AI contribution fields in CE

2.1. Design, development and maintenance of circular products

A fundamental requirement of CE products is to innovate in terms of the utility and value of products, components and materials at any time (Ghoreishi & Happonen, 2020) of their life cycle. This increases their lifetime and that of the materials they are composed of: reuse cycles, repair, recycling of components, etc. To fulfil this requirement, AI is used as a useful tool. AI improves and accelerates the development of new products, components and materials suitable for a circular economy through iterative design processes aided by machine learning (Akinode & Oloruntoba, 2020). This enables the testing and development of prototypes and innovations meeting circularity product requirements. As a result, the amount of resources required and the production of product waste can be significantly reduced. At the same time, AI helps to predict the variation of material requirements over time, their overall durability and potential toxicity (Pregowska et al., 2022). In terms of maintenance of circular products, AI is used to analyze data collected throughout the product life cycle. Based on these, real-time performance improvements are made or it is determined whether a returned product should be reused, remanufactured or recycled (Blunck et al., 2019).

2.2. Managing circular business models

AI increases the competitive strength of business models in the circular economy, such as product, service and leasing. By combining real-time and historical product and user data, AI contributes to increasing product circulation and asset utilization, through pricing and demand forecasting, predictive maintenance, and intelligent inventory management (Akinode & Oloruntoba, 2020). Di Vaio and his team (2020) demonstrate the involvement and importance of AI in the introduction of new business models implementing CE principles (Di Vaio et al., 2020). Some of the main advantages of AI in the management of circular business models are associated with the ability to analyze large sets of consumer data in real time, informing predictive demand and pricing (Aktepe et al, 2021). Another advantage is the so-called predictive maintenance, where it can extend the life of equipment by minimizing costs and the use of spare parts (Carvalho et al., 2019), before machine failure and business process shutdown.

2.3. Optimising circular infrastructure and business

Among the basic principles of the circular economy is the closure of the complete production cycle. To achieve this, a functioning reverse logistics system is required, with efficient processes for sorting and disassembling products, remanufacturing components and recycling materials (Akinode & Oloruntoba, 2020). AI has the resource to support the circulation of products and materials throughout the supply chain. For example, through IoT and AI algorithms, high quality in recognition and imaging can be achieved (Wilson et al., 2022). The combination of IoT with robotics allows to significantly increase the quality of sorting processes of mixed material streams (Schmidt et al., 2021), differentiate waste, facilitate recycling minimizing resource waste (Roberts et al., 2024). Another aspect accounting for AI contributions in the circular economy focuses on energy optimization in manufacturing processes. For example, businesses running large database arrays require large electricity consumption for server maintenance and cooling. AI has the ability to analyse and optimize the energy consumption used (Roberts et al., 2024).

- Main groups of risks related to the application of AI in the circular economy

It is a well-known fact that every business is accompanied by the manifestation of a multitude of risks of different importance and frequency. Businesses part of the circular economy are no exception. The purpose of this part of the paper is to identify key risks associated with the sustainable management of closed-loop manufacturing supply chains. While there are a multitude of interrelated risks on this spectrum, the paper focuses only on this group.

The complexity of relationship management in CE comes from the involvement of multiple stakeholders throughout the chain. This requires a high degree of collaboration between parties and harmonization of their decisions (Alexandris et al., 2018). Cooperative networks, with full systems compatibility (Ramadoss et al., 2018), are needed to provide information on the status of materials and production throughout the chain. In turn, the open nature of data collection and analysis exacerbates the risks associated with information privacy (Roberts et al., 2024). Risks associated with governance and decision-making fall into the same range of risks. In a sustainable supply chain, proper decision making is important for effective implementation of CE, but its alignment with other actors and a complex and lengthy process. Knowledge and information sharing are key factors in supply chain decision making. Furthermore, communication between partners is supported by the information technology infrastructure (Govindan & Hasanagic, 2018), which poses several technical risks. Common decisions in the supply chain also provoke several risks related to not obtaining unanimous opinions and their compatibility between partners.

In a closed production cycle involving multiple actors, several risks related to the overall integration and integrity of the data become apparent. CE requires information to be shared between different actors, but this is not always a good option for them. Their concerns are primarily related to the sharing of know-how and new knowledge, which is of a confidential nature. Exporting new knowledge through collaboration with suppliers is problematic in situations of technology confidentiality (Govindan et al., 2014), as it can harm their competitiveness (Rizos et al., 2016). Integration with IT systems and scheduling issues are other causes of supply chain integrity (Bressanelli et al., 2018).

Although schematically viewed without going into detail it becomes apparent that circular production is difficult to achieve. Apart from the range of risks associated with the integration of the actors in between, it must be borne in mind that the manifestation of a risk is not isolated. The occurrence of the risk will have an impact on all actors in the chain, and will also generate a knock-on effect, triggering the manifestation of a range of other risks. This makes it necessary to look for intelligent solutions to risk treatment.

- Research methodology

The methodology aims at establishing the path and location of the different stages that the different actors in the circular product chain must go through in order to minimize the risk of unfair decisions harming the interests of all stakeholders. In conceptualising this mechanism, the positive effect that it can add value was sought. To obtain it, solutions based on artificial intelligence are identified and it is shown how, through it, additional intelligent analysis can be performed to improve the overall process related to decision making affecting all participants. The limitation here is that while there is a great deal of similarity in the treatment of individual risk groups, each business and business organization has specificities that must be accounted for. This in turn requires further individual analysis, which is not the subject of research in this paper.

- Results and discussion

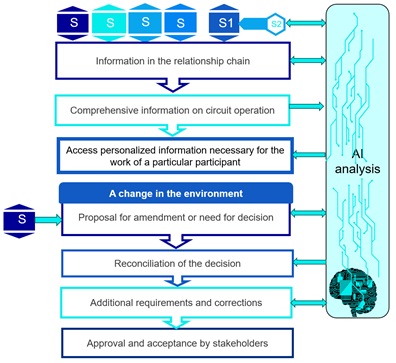

The results of this study are summarized to present a conceptual framework for managing relationships and shared decisions in a circular producer chain. For its better perception, it is presented in schematic form in Fig. 2.

Figure 2. Conceptual diagram for intelligent treatment of risk associated with closed-loop relationships of circular products

It should be noted here that the mentioned concept assumes that the whole process is supported by intelligent analysis performed using AI and ML (machine learning). The specific algorithms and tools are not the subject of research here. To illustrate the concept, it is important to show how the whole process is supported rather than the specific intelligent toolkit. This solution is suitable for treating the risks associated with making decisions that have an impact on the activities of all actors in the circular product chain. The concept goes through the following steps:

– Identify all stakeholders in the chain of relationships. In the first place, it is necessary to illustrate all actors involved in the circular product. They can be conventionally divided into direct stakeholders (S), indirect stakeholders (S1). S refers to all those who are directly involved in the creation of the circular product or it is all the main actors in the chain. In their interrelationship the risks with the highest frequency and severity of consequences arise. S1 are all stakeholders who are relevant to the process but not directly involved, such as regulators. The concept foresees conducting an intelligent analysis of the presence of new actors. This is done by semantic analysis of unstructured databases and online information. Thus, if an indirect actor (S2) appears then it will be recognized and its benefits and threats to the whole chain will be identified. AI analysis examines the legal robustness of potential actors, requirements for dealing with them and their reputation. From this analysis comes approval or not for inclusion in the chain.

– Information in the chain of relationships. Secondly, it is necessary to define all the information needed to work in the chain. It is conventionally divided into two groups: information public to the chain, necessary to carry out the business processes of all participants; and personal information concerning the activities of each individual participant. At this stage, it is important to correctly define access rights to the information in the chain according to the needs of the actors and the security requirements of each actor.

– Change under the influence of environmental dynamics. This is where the risk treatment mechanisms of this conceptual model come into play. Change (the need for a solution) can be triggered either by a stakeholder and/or by the AI. The suggestion of an amendment or need for a decision prompted by the system is based on informed recommendations and decisions from the ML and the AI. Alternatively, the decision may arise from a specific stakeholder and or multiple stakeholders. In order to minimize risk, it is required to be treated predicatively, i.e., the given decision must be agreed upon by all stakeholders before tensions arise between them. This is where the benefits of system intelligence can be seen. The AI conducts an analysis with the possible consequences for each specific participant. This allows obtaining an adequate analysis of multiple interrelated factors in real time. On this basis, each participant reconciles the decision with options to specify additional conditions or modifications in detail. The AI summarizes the solutions and suggests alternatives that would best satisfy all parties.

– Coordination in the chain. Intelligent system sending to all participants and visualizing the specifics that directly affect their interests and activities.

– Analysing decisions and giving suggestions. In the next iteration, participants have the alternative to accept the proposed solution and or propose additional requirements to it. The number of iterations here continues until agreement is reached in the chain of relationships.

– Generalization of proposals and AI analysis. By intelligently generating the “hit solution”, all participants obtain the best alternative within the specific parameters relative to their activity.

– Validation by stakeholders. The final stage is followed by validation of the solution by all parties and passing its action.

- Conclusion

By using an intelligent risk treatment system related to closed-loop product chain relationships, disputes and inconsistencies between the participants in the circular product chain are reduced. Everyone is informed about decisions that affect the entire chain, and the process is greatly facilitated and improved through the various AI mechanisms yielding spatial analytics involving large data sets and directions for analysis. The concept should be developed in further research, taking into account the constraints related to access to the intellectual rights of the individual actors, sharing and protection of company secrets.

Acknowledgements

This article was financially supported by the UNWE Science Fund (contract No. 5/2023).

REFERENCES

Akinode, J. & Oloruntoba, S. (2020). Artificial Intelligence in the Transition to Circular Economy. American Journal of Engineering Research, 9(6), 185 – 190.

Aktepe, A., Yanik, E. & Ersöz, S. (2021). Demand Forecasting Application with Regression and Artificial Intelligence Methods in a Construction Machinery Company. Journal of Intelligent Manufacturing, 32, 1587 – 1604. https://doi.org/10.1007/s10845-021-01737-8

Alexandris, G., Katos, V., Alexaki, S. & Hatzivasilis, G. (2018). Blockchains as Enablers for Auditing Cooperative Circular Economy Networks. In IEEE 23rd international workshop on computer aided modeling and design of communication links and networks (CAMAD) (pp. 1 – 7). IEEE. https://doi.org/10.1109/CAMAD.2018.8514985

Barteková, E. & Börkey, P. (2022). Digitalisation for the Transition to a Resource Efficient and Circular Economy. OECD Environment Working Papers, 192. https://doi.org/10.1787/6f6d18e7-en

Blunck, E., Salah, Z. & Kim, J. (2019). Industry 4.0, AI and Circular Economy – Opportunities and Challenges for a Sustainable Development. Proceedings of Dubrovnik International Economic Meeting (DIEM), 17 – 42. https://www.diem-dubrovnik.com/diem/files/2019/Abstracts_DIEM_2019.pdf

Bressanelli, G., Adrodegari, F., Perona, M. & Saccani, N. (2018). The Role of Digital Technologies to Overcome Circular Economy Challenges in PSS Business Models: An Exploratory Case Study. Procedia CIRP, 73, 216 – 221. https://doi.org/10.1016/j.procir.2018.03.322

Carvalho, T., Soares, F., Vita, R., Francisco, R., Basto, J. & Alcalà, S., (2019). A Systematic Literature Review of Machine Learning Methods Applied to Predictive Maintenance. Computers & Industrial Engineering, 137, 106024. https://doi.org/10.1016/j.cie.2019.106024

Chauhan, C., Dhir, A., Akram, M. & Salo, J. (2021). Food Loss and Waste in Food Supply Chains: A Systematic Literature Review and Framework Development Approach. Journal of Cleaner Production, 295, 126438. https://doi.org/10.1016/j.jclepro.2021.126438

Chauhan, C., Parida, V. & Dhir, A. (2022). Linking Circular Economy and Digitalisation Technologies: A Systematic Literature Review of Past Achievements and Future Promises. Technological Forecasting Social Change, 177, 121508. https://doi.org/10.1016/j.techfore.2022.121508

Da Silva, T. & Sehnem, S. (2022). The Circular Economy and Industry 4.0: Synergies and Challenges. Revista de Gestão, 29(3), 300-313. https://doi.org/10.1108/REGE-07-2021-0121

Di Vaio, A., Palladino, R., Hassan, R. & Escobar, O. (2020). Artificial Intelligence and Business Models in the Sustainable Development Goals Perspective: A Systematic Literature Review. Journal of Business Research, 121, 283 – 314. https://doi.org/10.1016/j.jbusres.2020.08.019

Ghisellini, P., Cialani, C., & Ulgiati, S. (2016). A Review on Circular Economy: The Expected Transition to a Balanced Interplay of Environmental and Economic Systems. Journal of Cleaner production, 114, 11 – 32. https://doi.org/10.1016/j.jclepro.2015.09.007

Ghoreishi, M. & Happonen, A. (2020). New Promises AI Brings into Circular Economy Accelerated Product Design: A Review on Supporting Literature. E3S Web of Conferences, 158, 06002. https://doi.org/10.1051/e3sconf/202015806002

Govindan, K. & Hasanagic, M. (2018). A systematic Review on Drivers, Barriers, and Practices Towards Circular Economy: A Supply Chain Perspective. International Journal of Production Research, 56(1-2), 278 – 311. https://doi.org/10.1080/00207543.2017.1402141

Govindan, K., Kaliyan, M., Kannan, D. & Haq, A. (2014). Barriers Analysis for Green Supply Chain Management Implementation in Indian Industries Using Analytic Hierarchy Process. International Journal of Production Economics, 147, 555 – 568. https://doi.org/10.1016/j.ijpe.2013.08.018

Morseletto, P. (2020). Restorative and Regenerative: Exploring the Concepts in the Circular Economy. Journal of Industrial Ecology, 24(4), 763 – 773. https://doi.org/10.1111/jiec.12987

Noman, A., Akter, U., Pranto, T. & Haque, A. (2022). Machine Learning and Artificial Intelligence in Circular Economy: A Bibliometric Analysis and Systematic Literature Review. Annals of Emerging Technologies in Computing (AETiC), 6(2), 13 – 40. https://doi.org/10.33166/AETiC.2022.02.002

Pathan, M., Richardson, E., Galvan, E. & Mooney, P. (2023). The Role of Artificial Intelligence within Circular Economy Activities – A View from Ireland. Sustainability, 15(12), 9451. https://doi.org/10.3390/su15129451

Pregowska, A., Osial, M., & Urbanska, W. (2022). The Application of Artificial Intelligence in the Effective Battery Life Cycle in the Closed Circular Economy Model – A Perspective. Recycling, 7(6), 81. https://doi.org/10.3390/recycling7060081

Ramadoss, T. S., Alam, H., & Seeam, R. (2018). Artificial Intelligence and Internet of Things Enabled Circular Economy. The International Journal of Engineering and Science, 7(9), 55 – 63.

Rathinamoorthy, R. (2019). Circular fashion. In S. S. Muthu (Ed.), Circular Economy in Textiles and Apparel: Processing, Manufacturing, and Design (pp. 13 – 48). Woodhead Publishing. https://doi.org/10.1016/B978-0-08-102630-4.00002-9

Rizos, V., Behrens, A., Van Der Gaast, W., Hofman, E., Ioannou, A., Kafyeke, T., Flamos A., Rinaldi, R., Papadelis, S., Hirschnitz-Garbers, M. & Topi, C. (2016). Implementation of Circular Economy Business Models by Small and Medium-sized Enterprises (SMEs): Barriers and Enablers. Sustainability, 8(11), 1212. https://doi.org/10.3390/su8111212

Roberts, H., Zhang, J., Bariach, B., Cowls, J., Gilburt, B., Juneja, P., Tsamados, A., Ziosi, M., Taddeo, M. & Floridi, L. (2024). Artificial Intelligence in Support of the Circular Economy: Ethical Considerations and a Path Forward. AI & Society, 39(3), 1451 – 1464. https://doi.org/10.1007/s00146-022-01596-8

Schmidt, J., Auer, M., Moesslein, J., Wendler, P., Wiethoff, S., Lang‐Koetz, C., & Woidasky, J. (2021). Challenges and Solutions for Plastic Packaging in a Circular Economy. Chemie Ingenieur Technik, 93(11), 1751 – 1762. https://doi.org/10.1002/cite.202100110

Sterev, N., & Biolcheva, P. (2023). Intelligent Systems in the Circular Economy. In VIth International Conference on Governance and Strategic Management (ICGSM): ESG Standards and Securing Strategic Industries: Conference Proceedings (pp. 54 – 62). Burgas Free University. https://www.bfu.bg/uploads/pages/book-conf-2023.pdf

Wilson, M., Paschen, J., & Pitt, L. (2022). The Circular Economy Meets Artificial Intelligence (AI): Understanding the Opportunities of AI for Reverse Logistics. Management of Environmental Quality: An International Journal, 33(1), 9 – 25. https://doi.org/10.1108/MEQ-10-2020-0222

Ximenes, F., Björdal, C., Cowie, A. & Barlaz, M. (2015). The Decay of Wood in Landfills in Contrasting Climates in Australia. Waste management, 41, 101 – 110. https://doi.org/10.1016/j.wasman.2015.03.032