Miel Hofmann, Sudad H. Al-Obaidi

Mining University, Russia

Igor P. Kamensky

Scientific Research centre, Russia

https://doi.org/10.53656/nat2025-4.06

Abstract. This study presents a novel technique for developing complex oil reservoirs with bottom water. The method involves injecting freshwater below the oil-water contact (OWC) and subsequently stabilizing it with a polymer to create a barrier. This approach is designed to reduce water cut, enhance oil recovery (EOR), and sustain production rates in mature fields.

Based on an analysis of experimental and field data, criteria for the technology’s application have been established. A key mechanism is the reduction of permeability in terrigenous reservoirs following freshwater injection, a phenomenon confirmed by laboratory core studies. Using a radial hydrodynamic model, this study assessed the technology’s effects and performed a sensitivity analysis to optimize perforation placement and injected agent volume. The results can be used to evaluate not only freshwater but also other water-control agents, although field-specific core flow studies are necessary to justify any application.

The model also identified two primary mechanisms of bottom water inflow to production perforations. The first is water coning, which is driven by production-induced pressure gradients. The second mechanism is channeling along the casing string, which is caused by factors like poor cement quality or the presence of natural and induced fractures. Finally, a calculation of production losses resulting from this water flow was performed.

Keywords: Freshwater, OWC, Underlying water, Water cut, EOR

- Introduction

The primary focus of the modern oil and gas industry is to enhance the efficiency of hydrocarbon extraction from complex fields at a late stage of development. A large proportion of these hydrocarbon reserves are found in fields classified as “with bottom water” or water-floating (Al-Obaidi & Khalaf, 2019; Asuaje et al., 2025; Huang & Lin, 2020; Yang et al., 2022). Developing these areas is complicated by the rapid formation of a water cone drawn up toward vertical wells due to pressure depletion.

Currently, various agents and methods (gels, polymers, alkalis, fresh water, etc.) are used to limit water inflow (WIL) in complex oil and gas fields (Bai et al., 2023; Chang et al., 2021] Foutou et al., 2021; Han et al., 2022). These methods fundamentally aim to reduce the permeability of highly permeable, water-washed zones within the formation, allowing the low-permeability sections to be effectively utilized. A wide range of action mechanisms is known. In each specific case, the chosen method depends on the reservoir type, the geological structure of the deposit, and the technical and economic conditions (Al-Obaidi, 2015; Hassan et al., 2022; Malozyomov et al., 2023; Xu et al., 2020;).

One popular area of development is the use of fresh water, primarily due to its low cost compared to specialized chemical agents (gels, polymers, alkalis, surfactants). The effect of fresh water on permeability varies between high- and low-permeability reservoirs. In low-permeability, clay-filled reservoirs, a permeability reduction occurs due to clay swelling (Bourg & Ajo-Franklin, 2017; Liu et al., 2021; Zhao et al., 2024).

In highly permeable reservoirs with a low degree of clay content, permeability may also decrease due to migration of fine particles. Several studies (Chen et al., 2023; Knobloch et al., 2018; Li et al., 2023; Ligeiro et al., 2021) have performed qualitative and quantitative calculations of permeability reduction (ranging from 10 to 1000 times) during fresh water injection. It has been shown that in terrigenous reservoirs, introducing fresh water reduces the Van der Waals forces that hold fine particles on the pore walls. As a result, the fine particles migrate toward the pore throats. These particles then clog the narrow pore throats, generally resulting in a sharp decrease in permeability.

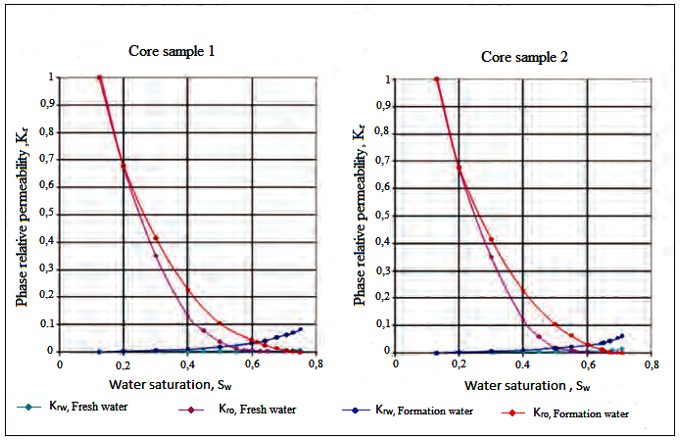

Experiments on oil displacement using various agents were carried out on linear core models (Al-Obaidi et al., 2022; Drozdov, 2022; Liu et al., 2020). The results demonstrated a 4-to-11-fold decrease in effective permeability for sandstones of the terrigenous Carboniferous strata during flooding with fresh (river) water (Fig. 1). It was concluded that fresh water is not recommended for flooding terrigenous deposits of the Lower Carboniferous due to its significant negative impact on the formation’s flow properties. Based on these studies, the reservoir pressure maintenance system transitioned to using bottom and formation water.

Figure 1. Linear core model with reduced effective permeability under freshwater displacement

This paper considers a technological solution: injecting a freshwater rim into the WOC zone to reduce permeability. This aims to delay bottom water breakthrough while simultaneously decreasing water cut and increasing oil production.

- Methodology and materials

The modeling approach utilizes the freshwater rim technique, which functionally resembles polymer flooding (Agi et al., 2018; Ding et al., 2020; Rai et al., 2015; Wang et al., 2022). This simulation is executed using the Eclipse 100 reservoir simulator, leveraging its dedicated Polymer section to model the effects of freshwater on the terrigenous formation.

2.1 Simulation Parameters

The interaction between the freshwater and the reservoir rock is defined by standard polymer modeling parameters, including the Recovery Resistance Factor (RRF) and the adsorption curve. The impact of freshwater on formation properties is explicitly implemented using the simulator keywords (Al-Obaidi et al., 2023; Ekanem et al., 2021; Haq et al., 2019; Olabode et al., 2024):

– Plyrock (Polymer rock properties)

– Plyads (Polymer Adsorption Functions)

2.2. Hydrodynamic Model Design

The model employs a variable-resolution grid optimized for accuracy in the critical zone and efficiency in the far-field.

– Near-Wellbore Zone: A high-precision grid is used, with a fine resolution of 0.1×0.1×0.1 m, ensuring an accurate description of dynamic processes immediately surrounding the wellbore.

– Periphery: The grid is systematically coarsened, with the dr parameter increasing up to 100 m at the model’s periphery.

The overall grid consists of 6,000 cells. This strategic coarsening maintains computational efficiency, resulting in a rapid calculation time that does not exceed 5 minutes. The primary objective of the hydrodynamic model is to simulate processes within the bottom-hole zone, specifically for optimizing Water Inflow Limitation (WIL) techniques (Luo et al., 2023; Sharma et al., 2000; Yudin et al., 2024).

- Model Parameters and Reservoir Characteristics

The main parameters included in the model correspond to the geological and physical characteristics of one of the Ural-Volga region deposits. The simulation utilizes the Eclipse 100 simulator, with fluid saturation set using the Leverett J-function.

The reservoir properties are:

– Total Reservoir Thickness: 10 m

– Oil-Saturated Thickness: 4.5 m

– Average Permeability: 100 mD

– Average Porosity: 0.2

– Oil Viscosity: 19.8 cP

Fluid densities used are:

– Oil: 894 kg/m3

– Formation Water: 1190 kg/m3

– Fresh Water (for injection): 1007 kg/m3

The well is completed with a 2 m perforation in the near-roof part of the reservoir, and the simulation covers a 2 year period.

- Analysis of Bottom Water Inflow Mechanisms

During production, two primary mechanisms contribute to bottom water inflow into the perforations:

- Water Coning: This is driven by pressure gradients within the formation.

- Fluid Circulation along the Casing: This is largely a well integrity issue, influenced by the quality of cementing and the presence of natural or man-made fracturing behind the casing.

A series of calculations was conducted to evaluate the impact of flow along the casing column by varying the included thickness. It is important to note that the hydrodynamic finite-difference scheme used does not account for the resistance to fluid circulation within the casing column. However, these calculations provide crucial insight into the potential effectiveness of repair and insulation work. In the case analyzed, losses from bottom water inflow along the casing column could reach up to 35% of the base production over the specified period.

2.5. Proposed Water Inflow Limitation (WIL) Technology

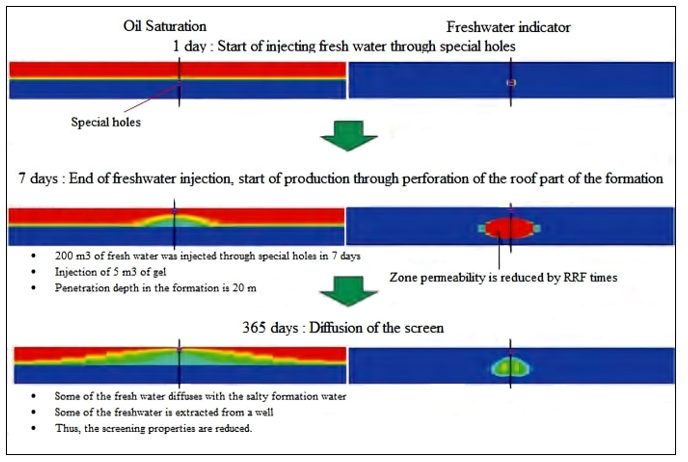

To effectively counteract the water coning effect, a more thorough intervention in the formation is essential. The proposed Bottom-hole Zone Treatment (BHT) technology is outlined as follows:

- Fresh Water Rim Injection: A 200 m3 fresh water rim is injected over 7 days through special openings positioned 1 – 2 m above the Oil-Water Contact (OWC). The optimal position of these openings was determined through prior optimization calculations.

- Fixation: A 5 m3 polymer solution is subsequently injected to stabilize and fix the fresh water rim.

- Isolation: Cement is used to fill the special openings to prevent any subsequent behind-the-casing flows.

Following the BHT, the well is returned to production through the initial two-meter perforation interval. The injection of the agent using this described WIL technology was simulated, and the subsequent effect on production was calculated (results are presented in Fig. 2).

Figure 2. Modelling of the BHT technology on a radial hydrodynamic model

- Calculations and discussions

3.1. Optimization of Special Opening Position

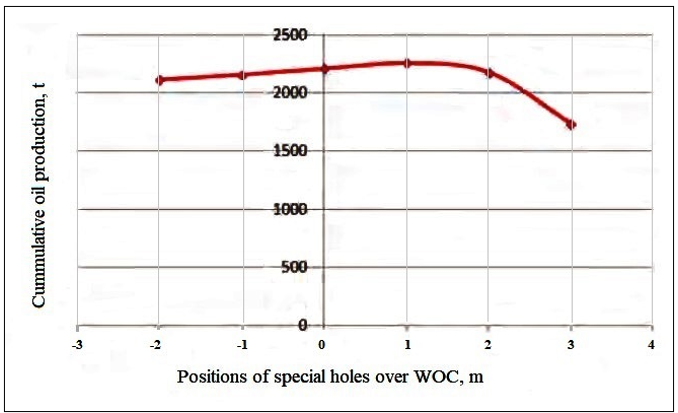

A critical series of calculations was conducted to determine the optimal placement of the special openings used for injecting the Water Inflow Limitation (WIL) agent (as illustrated in Figure 3).

The simulation results identified the most effective injection depth for the case study: an interval of 1 – 2 m above the Oil-Water Contact (OWC).

Figure 3. Optimization of the position of special holes during the implementation of the BHT

The optimal placement represents a balance between maximizing the screening effect of the injected rim and preserving the productive oil column.

– Impact of Downward Shift: Shifting the special openings downwards (closer to or below the OWC) leads to a decrease in WIL efficiency. This occurs because the freshwater rim’s screening properties deteriorate; placing the agent too close to the mobile formation water allows the water cone to bypass the treatment or causes the agent to be swept away more quickly.

– Impact of Upward Shift: Conversely, placing the special openings too high (further above the OWC) is detrimental because it blocks part of the effective oil-saturated thickness. This sacrifice of the productive zone reduces the potential oil inflow rate and is counterproductive to the overall goal of maximizing oil recovery.

This optimization confirms that successful WIL implementation relies heavily on accurately determining the OWC and precisely placing the fresh water rim to build an effective barrier without infringing upon the oil-saturated pay zone.

3.2. Optimization of Technology Parameters

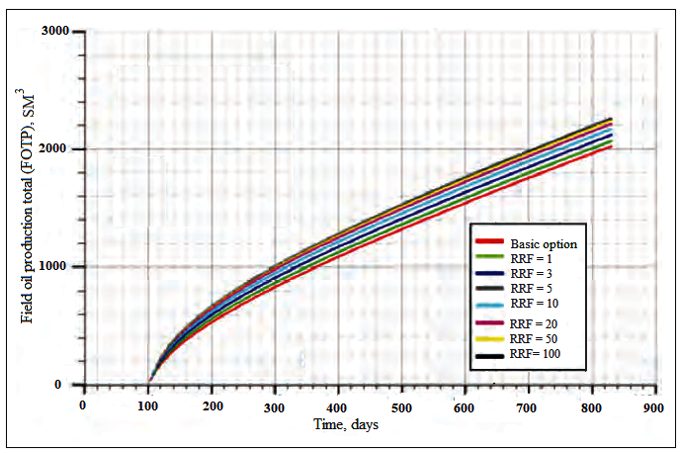

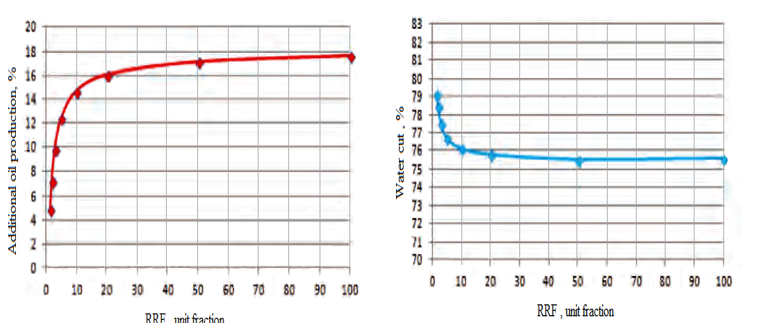

To fully optimize the Water Inflow Limitation (WIL) technology, a series of calculations was conducted to evaluate the effect of the treatment based on the Reduction in initial Water Permeability (RRF) within the impact zone (as shown in Figure 4 and Figure 5).

The RRF is a critical parameter that quantifies the local resistance introduced by the injected fresh water and polymer to the flow of formation water.

– Minimum Threshold: Based on the calculations, the WIL technology is not recommended for RRF values below 5. Below this threshold, the injected rim fails to provide sufficient screening or resistance to effectively suppress the water cone, rendering the treatment inefficient.

– Optimal Range: The associated risks (likely meaning the risk of treatment failure or adverse side effects) are minimal for RRF values between 10 and 20. This range represents the optimal balance where the treatment effectively restricts water inflow without causing detrimental side effects, such as unnecessarily blocking the flow of oil.

This analysis is essential for determining the required concentration and volume of the polymer solution needed to achieve an RRF between 10 and 20 for a successful, low-risk application of the WIL technology.

Figure 4. The influence of recovery resistance factor RRF on production parameters

Figure 5. Optimization of production parameters for the period under consideration by the number of RRF

3.3. Effectiveness of the Water Rim Screening (RRF Impact)

A series of calculations (Figures 4 and 5) was performed to specifically evaluate the impact of the Recovery Resistance Factor (RRF) on production parameters, assuming the absence of behind-the-casing flows.

The results show that the screening properties of the created water rim are highly effective, allowing for an average increase in cumulative oil production by 15% over the two-year period compared to the untreated case. This confirms the ability of the optimized RRF range (10 to 20, as previously discussed) to successfully suppress water coning and enhance oil recovery.

3.4. Optimization of Fresh Water Injection Volume

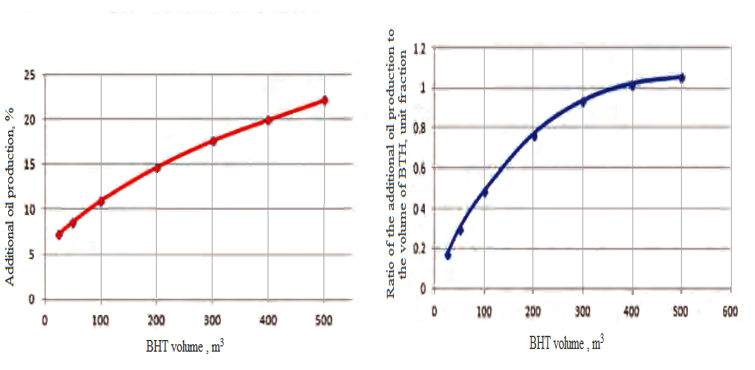

The impact of the fresh water injection volume on production parameters was also evaluated (Figure 6).

The analysis revealed a relationship with two key findings:

- Monotonic Increase in Production: Increasing the injection volume monotonically increases the percentage of additional oil production over the study period.

- Optimum Specific Efficiency: However, the specific efficiency of the impact (defined as the ratio of additional oil production to the injection volume) reaches an optimum. For the case under consideration, increasing the injection volume over 300 m3 was found to be ineffective in terms of cost-benefit, indicating a point of diminishing returns where the additional water does not significantly improve the barrier properties relative to the volume injected.

Figure 6. Optimization of production parameters during the specified period, informed by the volume of BHT

3.5. Advantages of the Proposed WIL Method

Beyond its technical effectiveness in mitigating water coning, the method offers significant technological and economic advantages:

– Low Cost of Injection Agent: The primary agent is fresh water, which has a substantially lower cost compared to specialized chemical compositions typically used in other conformance treatments.

– High Penetration Treatment: The method provides the technological and economic feasibility of treating the bottom-hole zone with a high depth of penetration (more than 10 m), ensuring the creation of a substantial and stable barrier deep within the reservoir to prevent water cone reformation.

- Conclusions

The investigation confirmed the feasibility of limiting bottom water inflow by pumping a rim of fresh water into the Oil-Water Contact (OWC) area through a special perforation interval, particularly in “water-sensitive” reservoirs.

Calculations performed on a radial sector hydrodynamic model indicate that when fresh water actively interacts with the reservoir rock, inducing reduced permeability, injecting a rim of fresh water can significantly screen the water coning effect. This approach has the potential to increase cumulative oil production by an average of 15% to 35% over two years. The optimal injection interval is determined to be 1.5 – 2 m above the OWC.

As anticipated, the screen’s efficiency depends on its radius, with an optimal volume of approximately 300 m3 identified for the 10 m thick water-oil reservoir; further increases in rim volume do not yield significant gains in efficiency. To achieve the necessary technological effect, a condition of at least a five-fold reduction in permeability (RRF ≥5) is required, with the optimal value being a ten-fold reduction or more.

The results obtained are valuable not only for evaluating the use of fresh water but also for analyzing other water-controlling agents, such as alkali solutions that promote clay swelling or reagents that form emulsions with formation water. However, substantiating the applicability of fresh water or any other agent necessitates detailed fluid flow studies on core material for each specific field.

REFERENCES

Agi, A., Junin, R., Gbonhinbor, J. & Onyekonwu, M. (2018). Natural polymer flow behaviour in porous media for enhanced oil recovery applications: a review. Journal of Petroleum Exploration and Production Technology, 8, 1349 – 1362. https://doi.org/10.1007/s13202-018-0434-7.

Al-Obaidi, S. H. (2015). The Use of Polymeric Reactants for EOR and Waterproofing. Journal of Petroleum Engineering and Emerging Technology, 1(1), 1 – 6.

Al-Obaidi, S. H., Hofmann, M. & Khalaf, F. H. (2023). Enhanced Oil Recovery In Terrigenous Oil Fields Using Low-Salt Water. Natural Sciences and Advanced Technology Education, 32(2), 107 – 124. https://doi.org/10.53656/nat2023-2.01.

Al-Obaidi, S. H., Hofmann, M., & Smirnova, V. (2022). Improvement of oil recovery in hydrocarbon fields by developing polymeric gel-forming composition. Natural Sciences and Advanced Technology Education, 31(5), 425 – 434. https://doi.org/10.53656/nat2022-5.02.

Al-Obaidi, S. H. & Khalaf, F. (2019). Development of traditional water flooding to increase oil recovery. International Journal of Scientific & Technology Research, 8(1), 177 – 181.

Asuaje, M., Rincón, N., Ratkovich, N., Pinilla, A. & Nieto, R. (2025). Water Inflow Controller Devices as a Solution for Production for Mature Oil Fields: A Literature Review. Processes, 13(1), 144. https://doi.org/10.3390/pr13010144.

Bai, Y., Liu, Y., Yang, K. & Lang, Y. (2023). Application and Research Prospect of Functional Polymer Gels in Oil and Gas Drilling and Development Engineering. Gels, 9(5), 413. https://doi.org/10.3390/gels9050413.

Bourg, I. C. & Ajo-Franklin, J. B. (2017). Clay, Water, and Salt: Controls on the Permeability of Fine-Grained Sedimentary Rocks. Accounts of Chemical Research, 50(9), 2067 – 2074. https://doi.org/10.1021/acs.accounts.7b00261.

Chang, W. J., Al-Obaidi, S. H. & Patkin, A. A. (2021). The use of oil-soluble polymers to enhance oil recovery in hard to recover hydrocarbons reserves. International Research Journal of Modernization in Engineering Technology and Science, 3(1), 982 – 987.

Chen, X., Li, Y-Q., Liu, Z.-Y., Trivedi, J., Gao, W.-B. & Sui, M.-Y. (2023). Experimental investigation on the enhanced oil recovery efficiency of polymeric surfactant: Matching relationship with core and emulsification ability. Petroleum Science, 20(1), 619 – 635. https://doi.org/10.1016/j.petsci.2022.11.002.

Ding, L., Wu, Q., Zhang, L. & Guérillot, D. (2020). Application of Fractional Flow Theory for Analytical Modeling of Surfactant Flooding, Polymer Flooding, and Surfactant/Polymer Flooding for Chemical Enhanced Oil Recovery. Water, 12(8), 2195. https://doi.org/10.3390/w12082195.

Drozdov, N. A. (2022). Filtration studies on cores and sand packed tubes from the Urengoy field for determining the efficiency of simultaneous water and gas injection on formation when extracting condensate from low-pressure reservoirs and oil from oil rims. Journal of Mining Institute, 257, 783 – 794. https://doi.org/10.31897/PMI.2022.71.

Ekarem, E., Rücker, M., Yesufu-Rufai, S., Spurin, C., Ooi, N., Georgiadis, A., Berg, S. & Luckham, P. F. (2021). Novel adsorption mechanisms identified for polymer retention in carbonate rocks. JCIS Open, 4, 100026. https://doi.org/10.1016/j.jciso.2021.100026.

Foutou, T. V., Dai, C., Shaikh, A., Li, J., Sun, N., Yang, N. & Zhao, G. (2021). Chromatography and oil displacement mechanism of a dispersed particle gel strengthened Alkali/Surfactant/Polymer combination flooding system for enhanced oil recovery. Colloids and Surfaces, A: Physicochemical and Engineering Aspects, 610, 125642. https://doi.org/10.1016/j.colsurfa.2020.125642.

Han, J., Sun, J., Lv, K., Yang, J. & Li, Y. (2022). Polymer Gels Used in Oil-Gas Drilling and Production Engineering. Gels, 8(10), 637. https://doi.org/10.3390/gels8100637.

Haq, B., Liu, J., Liu, K., Malaki, E. & Al-Shehri, D. (2019). Modification of Eclipse simulator for microbial enhanced oil recovery. Journal of Petroleum Exploration and Production Technology, 9, 2247 – 2261. https://doi.org/10.1007/s13202-019-0608-y.

Hassan, A. M., Al-Shalabi, E. W. & Ayoub, M. A. (2022). Updated Perceptions on Polymer-Based Enhanced Oil Recovery toward High-Temperature High-Salinity Tolerance for Successful Field Applications in Carbonate Reservoirs. Polymers, 14(10), 2001. https://doi.org/10.3390/polym14102001.

Huang, Q. H. & Lin, X. Y. (2020). Prediction of water breakthrough time in horizontal Wells in edge water condensate gas reservoirs. E3S Web of Conferences, 213, 02009. http://dx.doi.org/10.1051/e3sconf/202021302009.

Knobloch, L. O., Hincapie, R. E., Födisch, H. & Ganzer, L. (2018). Qualitative and Quantitative Evaluation of Permeability Changes during EOR Polymer Flooding Using Micromodels. World Journal of Engineering and Technology, 6, 332 – 349. https://doi.org/10.4236/wjet.2018.62021.

Li, M, Qu, Z., Wang, M. & Ran, W. (2023). The Influence of Micro-Heterogeneity on Water Injection Development in Low-Permeability Sandstone Oil Reservoirs. Minerals, 13(12), 1533. https://doi.org/10.3390/min13121533.

Ligeiro, T. S., Vaz, A. & Chequer, L. (2021). Forecasting the impact of formation damage on relative permeability during low-salinity water flooding. Journal of Petroleum Science and Engineering, 208, 109500. https://doi.org/10.1016/j.petrol.2021.109500.

Liu, K., Wang, D., Sheng, J. J. & Li, J. (2021). Review of the Generation of Fractures and Change of Permeability due to Water-Shale Interaction in Shales. Geofluids, 1, 1748605. https://doi.org/10.1155/2022/1748605.

Liu, Z., Wu, G. & Wei, C. (2020). Physical experiments and numerical simulations of viscosity reducer flooding for ordinary heavy oil. Journal of Petroleum Science and Engineering, 192, 107194. https://doi.org/10.1016/j.petrol.2020.107194.

Luo, W., Kottsova, A., Vardon, P. J., Dieudonné, A. C. & Brehme, M. (2023). Mechanisms causing injectivity decline and enhancement in geothermal projects. Renewable and Sustainable Energy Reviews, 185, 113623. https://doi.org/10.1016/j.rser.2023.113623.

Malozyomov, B. V., Martyushev, N. V., Kukartsev, V. V., Tynchenko, V. S., Bukhtoyarov, V. V., Wu, X., Tyncheko, Y. A. & Kukartsev, V. A. (2023). Overview of Methods for Enhanced Oil Recovery from Conventional and Unconventional Reservoirs. Energies, 16, 4907. https://doi.org/10.3390/en16134907.

Olabode, O., Oni, B., Dike, H., Akinsanya, O., Ajidahun, J. & Olaniyan, D. (2024). Investigating the effect of salt concentration on oil recovery during guar gum polymer flooding: A simulation study. Results in Engineering, 22, 102269. https://doi.org/10.1016/j.rineng.2024.102269.

Rai, S. K., Bera, A. & Mandal, A. (2015). Modelling of surfactant and surfactant–polymer flooding for enhanced oil recovery using STARS (CMG) software. Journal of Petroleum Exploration and Production Technology, 5, 1 – 11. https://doi.org/10.1007/s13202-014-0112-3.

Sharma, M. M., Pang, S., Wennberg, K. E. & Morgenthaler, L. N. (2000). Injectivity Decline in Water-Injection Wells: An Offshore Gulf of Mexico Case Study. SPE Production & Facilities, 15, 6 – 13. https://doi.org/10.2118/60901-PA.

Wang, J. C., Hofmann, M. & Al-Obaidi, S. H. (2022). Modelling the development of oil rim using water and gas injection. Natural Science and Advanced Technology Education, 31(3), 279 – 292. https://doi.org/10.53656/nat2022-3.01.

Xu, Z.-X., Li, S.-Y., Li, B.-F., Chen, D.-Q, Liu, Z.-Y. & Li, Z.-M. (2020). A review of development methods and EOR technologies for carbonate reservoirs. Petroleum Science, 17, 990 – 1013. https://doi.org/10.1007/s12182-020-00467-5.

Yang, Y., Li, F., Zhang, W., Li, X. & Pei, B. (2022). The continuous pack-off technology: A novel water-control method and application to offshore horizontal wells of limestone reservoir. Journal of Petroleum Science and Engineering, 211, 110137. https://doi.org/10.1016/j.petrol.2022.110137.

Yudin, A., Eltaher, E., Al-Yaseen, A., Al-Jalal, Z. & Faisal, M. (2024). Water Wells Injectivity Enhancement via Hydraulic Fracturing in Open Hole Completions. SPE Caspian Technical Conference and Exhibition. https://doi.org/10.2118/223395-MS.

Zhao, D., Xie, W., Zhu, J., Li, B., Wang, L., Chen, T., Sheng, Y & Huang, X. (2024). Oil Removal Technology for Water Injection in Low-Permeability Reservoirs: A Micro-Vortex Flow Approach. Processes, 12(6), 1092. https://doi.org/10.3390/pr12061092.

Prof. Dr. Miel Hofmann

ORCID iD: 0000-0001-5889-5351

Department of Petroleum Engineering

Mining University, Russia

E-mail: hof620929@gmail.com

Prof. Dr. Sudad H. Al-Obaidi

ORCID iD: 0000-0003-0377-0855

Department of Petroleum Engineering

Mining University, Russia

E-mail: drsudad@gmail.com

Prof. Dr. Igor P. Kamensky

ORCID iD: 0000-0001-7254-4021

Scientific Research Centre, SPB, Russia

E-mail: kamensky962@gmail.com

>> Download the article as a PDF file <<